Braillo Braille Printers – See What Sets Them Apart…

Producing Braille at high speeds while maintaining quality is a demanding mechanical process which requires a heavy-duty, precision-made Braille printer in order to meet these rigorous demands. As opposed to personal use Braille printers, a production Braille printer is designed to not only emboss Braille quickly, but built for continuous operation – as in 15+ hours of use at a time, with the user only stopping to reload paper no more than once per hour (when using rolls, the user may only have to stop once per day). On the other hand, personal Braille printers are built to produce low quantities of Braille documents. They can be great machines for low volume Braille printing, however, due to their construction and paper handling methods, they are not suited to produce large volumes of Braille documents for businesses, schools or government entities.

Hence, Braillo Braille printers are the preferred choice by nearly all major Braille production centers, because they are specifically built to handle the heavy demands of true Braille production.

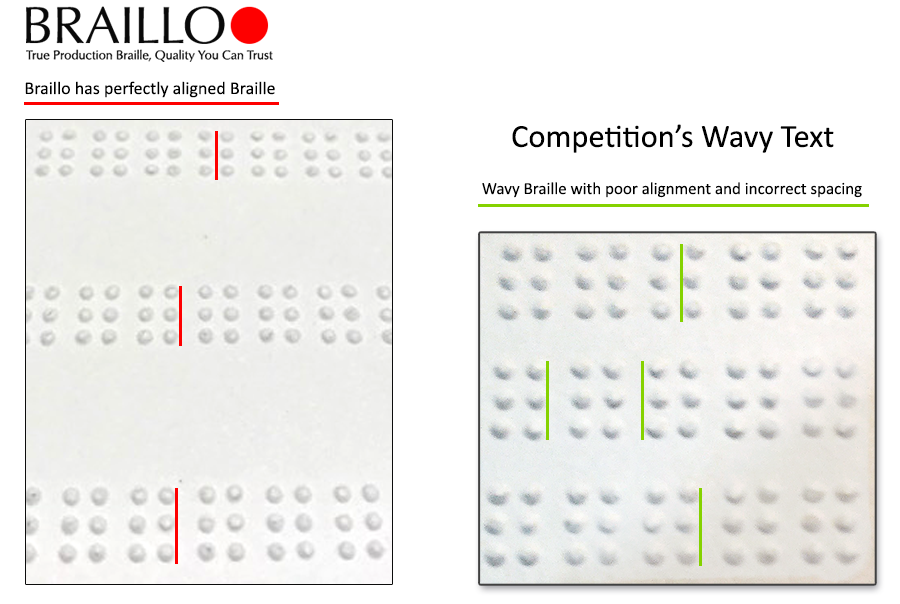

Production Braille printing is on a magnitude more demanding than consumer Braille printing. Manufacturer’s specifications aside, look at the quality of the Braille printer, its components and ask for references.

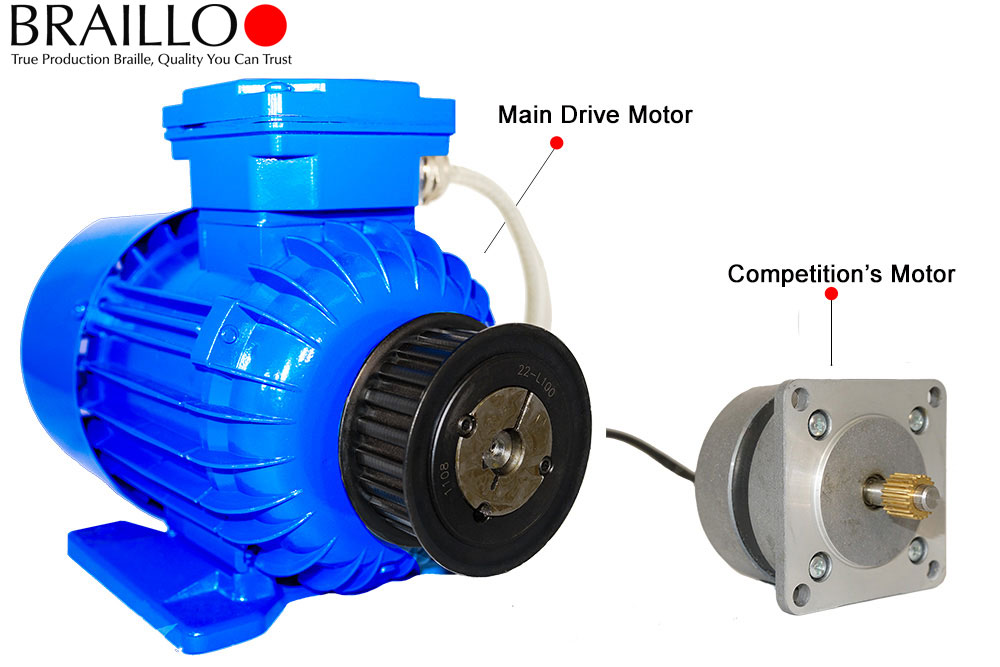

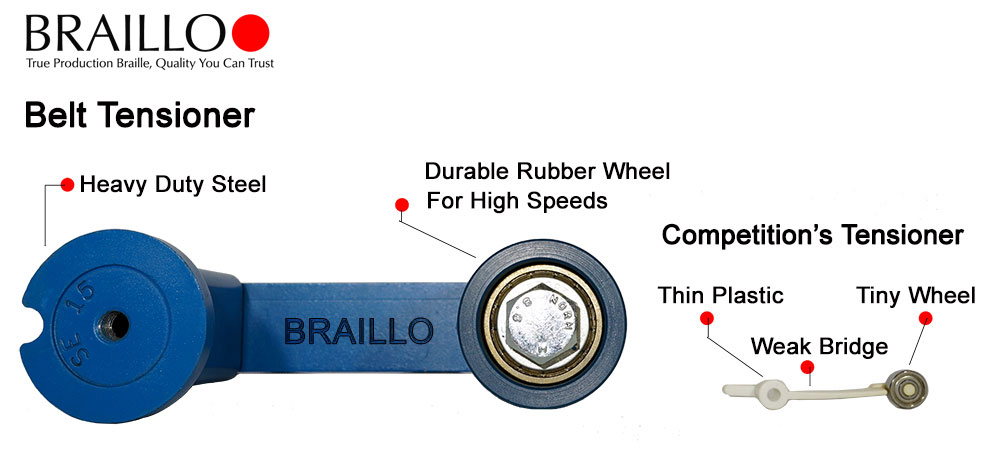

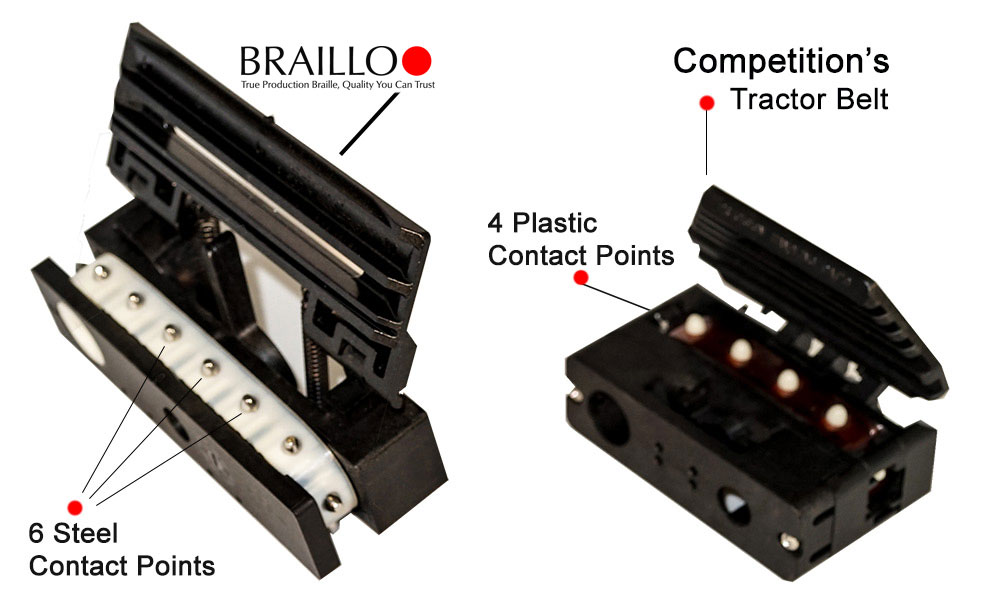

To demonstrate the differences between Braillo production Braille printers and those of its competitors, compare the mechanical parts. When critical parts such as these fail, Braille production stops. Looking at side-by-side comparisons of just a few of the parts below, which Braille printer would you trust to meet your Braille production requirements? Click on any image to enlarge it to see the obvious: Braillo is in a class of its own when it comes to production Braille printing.

Investing in A Braillo Braille Printer

Braillo is the world’s leading and largest manufacturer of true production Braille printers. Braillo Braille printers are built to serve high volume Braille printing, starting with the Braillo 300 S2 and all the way up to large-scale, high speed Braille Book/magazine production of the Braillo 650 SF, which folds, adds a cover and staples a book/magazine.

Braillo is often asked why it’s production Braille printers are heavier, larger and more expensive when compared to the lower-priced alternatives sold by its competitors. The answer is clear: Braillo builds heavy-duty, high quality, durable printers for true, large-scale Braille production. Braillo’s competitors assemble personal Braille printers with consumer-grade parts, and sell them as production Braille printers – there is just no comparison between the two. Initial acquisition cost does not equal total cost, and over a several year period, a Braillo printer is more cost-effective when you factor in downtime, repairs and replacement costs, all of which are associated with buying a lower-priced alternative.

When you purchase a Braillo printer, you are investing in a machine that will produce high quality Braille documents, books and magazines for decades. Countless Braillo printers from the 1980’s are still being used today – no other manufacturer can say that.